Chrome steel elements could degrade over time when they’re uncovered to inner and exterior elements that trigger corrosion, which may value amenities important money and time. Deteriorated elements could require repairs or alternative, both of which may end up in unplanned downtime for the system concerned (Fig. 1).

Services ought to deploy elements of their fluid methods constructed from 316 stainless-steel, whose chromium ranges present further safety towards the injury corrosion can inflict.

In accordance with the Nationwide Affiliation of Corrosion Engineers (NACE), corrosion can value offshore and nearshore amenities greater than $1 billion every year. Fortuitously, a number of easy options exist that may mitigate or get rid of the issues earlier than they grow to be insurmountable for oil and gasoline corporations.

Earlier than particular identifications are made, groups should perceive what causes corrosion and what steps they will take to forestall it from worsening and placing the fluid system liable to failure. Then upkeep groups ought to establish which type of corrosion is harming their fluid methods by studying and understanding what units the different sorts aside. As soon as an entire understanding of which corrosion is affecting a system is reached, then groups can take motion.

Why stainless-steel corrodes. Nearly each steel on the earth can corrode underneath sure circumstances, however the harsh circumstances of oil and gasoline functions current particular challenges particularly for offshore installations.

Corrosion outcomes from electrochemical reactions and oxidation (lack of electrons) at an anode, or discount (gaining of electrons) at a cathode (Fig. 2). A standard instance is iron tubing, which can oxidize and launch two electrons. Water launched to the system could cause the iron to dissolve into Fe2 optimistic ions. On the identical time, the electrons could trigger a discount response, altering dissolved O2 into OH-, a negatively charged hydroxide ion.

Each pitting and crevice corrosion start when the oxide layer on the skin of the steel floor breaks down and creates area for corrosive supplies to do injury.

Vulnerable steel tubing will be present in analytical and course of instrumentation, hydraulic traces, and management and utility functions within the oil and gasoline industries. To keep away from preliminary corrosion injury, most methods are designed with stainless-steel that has a minimal of 10% chromium in its composition. Enough chromium ranges induce the creation of an oxide layer that helps sluggish and even stop corrosion. Even the strongest stainless steels can succumb to corrosion if environmental circumstances destroy that oxide layer. With out that layer, corrosion reactions could proliferate rapidly.

The 2 most typical corrosion sorts going through the oil and gasoline trade are pitting corrosion and crevice corrosion.

The variations between pitting and crevice corrosions. At many oil and gasoline amenities, a number of corrosion sorts could occur concurrently and destroy whole fluid methods within the course of due to the operation surroundings, supplies used, and course of fluids. The 2 most typical types of stainless-steel corrosion are pitting corrosion and crevice corrosion (Fig. 3).

Pitting corrosion: Pitting happens when the chromium layer is destroyed over time, leaving the naked steel beneath unprotected. When the naked steel is uncovered to corrosive options, injury will happen. Sometimes, the injury takes the type of small cavities, generally generally known as pits.

Pitting corrosion (left) and crevice corrosion (proper) signify important dangers to offshore oil and gasoline fluid methods. Services ought to be sure their groups are outfitted with the data to establish, restore, and stop both kind of corrosion.

Visible inspection could reveal the beginnings of pitting corrosion, however the quantity of misplaced materials beneath the floor can silently undermine a pipe’s efficiency. Within the worst-case eventualities, pitting corrosion can perforate tube partitions and end in expensive leaks. Left unaddressed, pitting corrosion can result in cracks in elements underneath tensile masses. If the surroundings incorporates excessive ranges of chloride (CI-), resembling seawater hitting offshore drilling platforms, pitting corrosion is much more possible, particularly if excessive temperatures are concerned.

A transparent sign that pitting corrosion is going on is reddish-brown iron oxide deposits on the floor in addition to the beginnings of precise pits. If CI-bearing water like seawater swimming pools and evaporates, the remaining resolution will grow to be much more corrosive. Maintain upward-facing surfaces away from standing water to forestall CI-induced pitting corrosion.

Crevice corrosion: The reason for crevice corrosion is much like pitting corrosion, that means that the oxide layer has damaged down. What makes crevice corrosion extra insidious is that it hardly ever occurs in plain sight. As a substitute, because the title implies, it happens in crevices, making it tougher to seek out and stop. Moreover, the huge and comparatively shallow pits that happen in crevice corrosion solely develop as soon as the method has begun. In most fluid methods, crevices are created between tubing and tube helps or clamps, between adjoining tubing runs, and underneath dust and deposits which have collected on the floor.

Regardless of how intelligent the design, crevices will inevitably occur. The tightest crevices pose the only biggest hazard to the integrity of the system’s stainless-steel elements. Crevices are notably problematic in offshore functions as a result of seawater can diffuse into the crevice with out entry to an outlet. The ensuing chemically aggressive surroundings doesn’t enable corrosion-causing ions to come back again out, leaving the complete floor prone to speedy corrosion.

Moreover, crevice corrosion typically stays hidden till a tubing clamp is eliminated, leaving it probably undetected for lengthy durations of time. Not like pitting corrosion, crevice corrosion happens at decrease temperatures as a result of it’s simpler to create a pit beneath a tube clamp or different such gadget.

Holding corrosion from occurring. The only approach to reduce corrosion is to teach upkeep groups about fundamental supplies data and instituting corrosion-prevention requirements for the power.

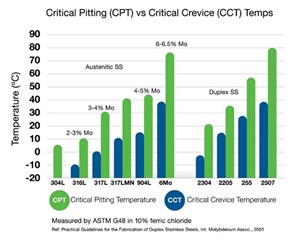

First, think about the selection of supplies for tubing functions, from the tubing itself to tube helps and clamps. Laboratory testing for vital pitting temperature (CPT) and significant crevice temperature (CCT)—in keeping with the ASTM G48 normal—is a useful instrument for evaluating supplies for use in corrosive environments. CPT testing evaluates the temperature at which pitting begins on a fabric in a particular corrosive resolution. Equally, CCT testing evaluates at what temperature crevice corrosion begins when a predefined crevice is positioned on a steel pattern in a corrosive resolution.

Supplies which have excessive values for CPT and CCT are typically extra appropriate to be used in comparable corrosive environments than supplies with low values. For instance, 304L has the bottom CPT worth of the supplies proven in (Fig. 4) whereas 6Mo and 2507 have the 2 highest CPT and CCT values. This means that 6Mo and 2507 are more likely to be extra immune to pitting and crevice corrosion than 304L and 316L in chloride-bearing options. You will need to remember the fact that these exams are helpful for comparability and materials choice however will not be predictive of when a fabric will fail in a real-life utility.

Vital Pitting Temperatures (CPT) and Vital Crevice Temperature (CCT) are necessary values used to find out which supplies will greatest resist corrosion in harsh working environments.

The 316L grade of stainless-steel (UNS S31603) tubing works properly in lots of installations so long as it’s saved clear, and temperatures will not be excessively excessive. In hotter climates, particularly in places the place salt deposits readily kind and in installations the place rust from carbon metal structural beams and flooring accumulates on stainless-steel surfaces, corrosion of 316L stainless-steel tubing is extra readily noticed. Nevertheless, because of the useful addition of molybdenum, 316L usually performs higher than 304L (UNS S30403) stainless-steel in these corrosive environments.

For conditions the place 316L is inadequate to fulfill the lifetime necessities of the applying, tubing constructed from tremendous austenitic (e.g., 6Mo or 6HN, UNS N08367) or tremendous duplex (e.g., 2507, UNS S32750) stainless steels affords considerably improved corrosion resistance. Moreover, the upper yield and tensile power of tremendous austenitic and tremendous duplex stainless steels make it simpler to construct methods that have to be rated to the next most allowable working strain (MAWP). Working along with your tubing and tube fittings provider for steerage in deciding on the suitable merchandise and supplies will help you keep away from expensive errors.

Along with supplies choice, cautious system practices are obligatory for stopping corrosion and minimizing the variety of places the place crevice corrosion can happen. One approach to mitigate crevice corrosion in a tube system is to keep away from inserting tubing immediately towards partitions or towards one another. When crevice corrosion of 316L stainless-steel tubing is noticed, one can substitute 316L tubing with extra corrosion-resistant tubing resembling 6Mo, which will be put in with cost-effective 316L tube fittings in recommended mixed-material engineered mixtures.

Why it issues. Oil and gasoline corporations are more and more underneath strain to maintain upkeep prices down, and sustaining fluid methods at peak efficiency is a necessary method to assist accomplish it. In actuality, which means ensuring the upkeep workforce understands easy methods to establish, right, and stop corrosion earlier than it damages a whole system.

Constructing a fundamental understanding of corrosion—what it appears like, the place it happens, and for what causes—amongst those that usually work with tubing methods will help stop materials failure and expensive repairs in addition to enhance system longevity.